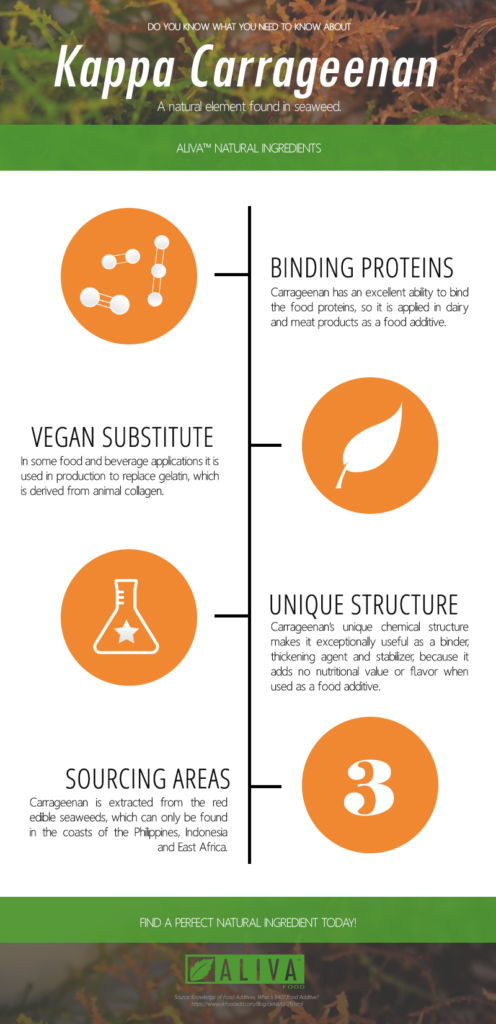

Carrageenan is one of the most known naturally extracted food additives, quite popular among manufacturers of food products. Applying Carrageenan in food processing helps reach multiple goals at once: this ingredient is cost-effective, naturally extracted, and highly efficient. Let’s see what are the advantages of using Carrageenan in food production. In fact, there are three widely known commercial types of carrageenan: Iota, Lambda and Kappa Carrageenan. The carrageenans function as emulsifiers, gelling agents, stabilizers and thickeners.

Kappa Carrageenan Powder

Being extracted from red seaweeds, carrageenans have a powder form and become plant soluble fiber. Thus, kappa carrageenan (or κ-Carrageenan) is tan to yellowish powder. Here are just some of Kappa Carrageenan properties, that make it different from Iota and Lambda carrageenan:

Kappa Carrageenan properties

- Easily soluble in hot water;

- Excellent water-retention capacity;

- Good gel condensation, ability to form a variety of different gels at room temperature;

- Thixotropic abilities;

- Resistant to low temperatures;

- Able to provide a slightly opaque or clear gel structure.

Refined Kappa Carrageenan in Food Processing

Thanks to its wide range of gelling and emulsifying properties, Kappa Carrageenan has a high reactivity in various formulations in the manufacturing of the following products:

- Dairy products: Kappa Carrageenan is vastly used in dairy, at very low concentrations it is able to prevent fractionation of milk constituents. This high reactivity with milk protein enables carrageenan to produce very economical and strong milk gels at very low levels (i.e. 0.05 – 0.2% w/w). More specific applications of Kappa Carrageenan in dairy products:

- Chocolate milk: this is one of the major applications because there’s no other ingredient with the same efficiency to stabilize chocolate milk by producing semi-gelled systems and to give the product a smooth mouthfeel achieving cocoa suspension.

- Processed cheese: as a gelling agent, Carrageenan helps achieve dairy protein reduction and reduce the production cost.

- Thickened milk drinks: for this kind of dairy beverages, Carrageenan is needed to suspend insoluble materials, improve mouthfeel, and stabilize emulsions.

- Greek yogurt: Carrageenan provides necessary stability and texture to those particular yogurts.

- Ice cream: in various ice creams, Carrageenan is added for better whey protection, delicate texture modification and viscosity control.

- Desserts: Carrageenan is a popular gelling agent in the production of desserts

- Hot-fill applications: to form and keep the shape of a product, provide creaminess and syneresis control, manufacturers tend to use Carrageenan if the hot-fill process involved.

- Toppings: Carrageenan provides a transparent flexible glaze that eliminates syneresis.

- Instant mousse: as a soft food, mousses that keep the shape, have good viscosity control, and improved foam structure, usually contain Carrageenan.

- Puddings and flans: Carrageenan is an essential gelling agent, thickener and syneresis control agent in the production of various puddings.

- Oil-free dressings: Carrageenan suspends particles in the product, improves texture and mouthfeel.

- Meat products: used in the processing of many meat products, Carrageenan is helpful in emulsifying, improving succulence and yield, enhancing binding of water and meat particles, improving sliceability and meat-like texture, enhancing elasticity and gummy bite sensation, helping meat protein dissolve, preventing shrinkage upon cooking and reducing cost.

- Sausage and Ham: Carrageenan improves the succulence, yield, and sliceability of these meat products.

Is Carrageenan safe to use?

Yes, Carrageenan is a safe food additive, which has been verified by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) and the United States Environmental protection Agency (EPA). JECFA certified that the consumption of carrageenan is not of concern and left recommendations on an Acceptable Daily Intake (ADI) unspecified. EPA included Carrageenan into the chemicals group verified to be of low concern based on experimental and modeled data.

How to use Kappa Carrageenan?

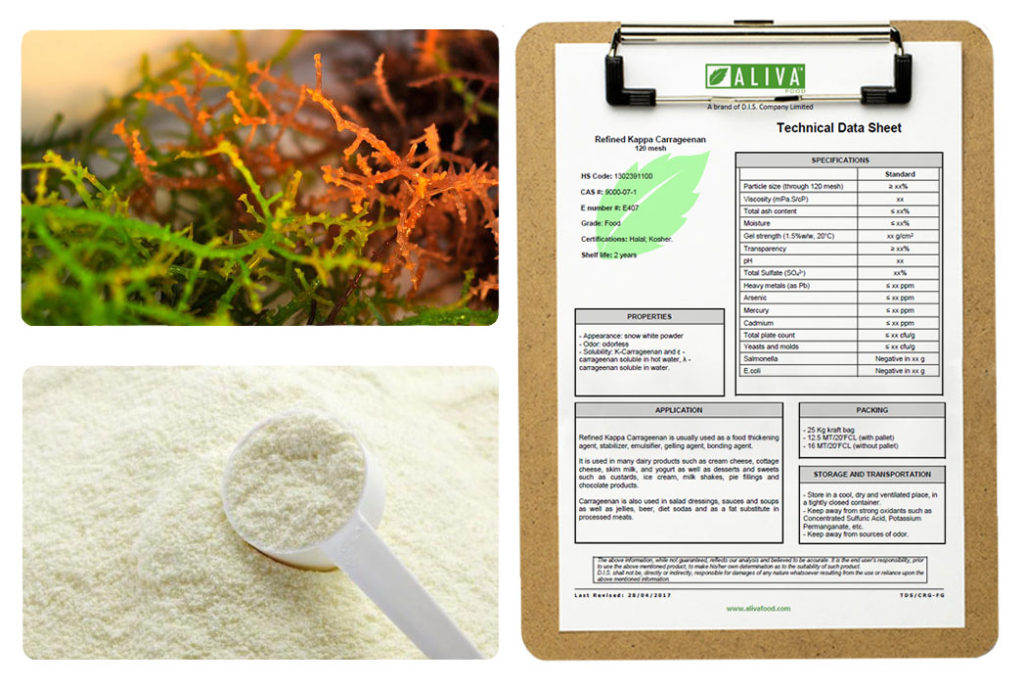

Any product requires a unique solution of Carrageenan to get a desired gelling or emulsifying effect. For some applications, like in meatballs or jelly drinks, it can be combined with such additives as Konjac Gum. To find the right specification for your products and business, it is better to consult a technical data sheet (TDS) of a supplier.

Get our TDS of Kappa Carrageenan: